This post may contain affiliate links(s). An affiliate link means I may earn advertising/referral fees if you make a purchase through my link,

without any additional cost to you. It helps to keep this site afloat. Thank you in advance for your support. If you like what we do here, maybe buy me a

coffee.

Canon's new stacked sensors and what this all means

With the announcement of the R3, Canon has announced they have jumped around 2 or 3 Sony sensor generations and are now capable of producing stacked sensors, and with the rumored Cinema cameras, it's obvious that Canon plans to quickly roll them out - everywhere.

We don't have any details on the R3, however, with the rumored cinema cameras, we now have some numbers that we can crunch. All the cinema cameras check out with a 17:9 aspect ratio sensor with either 4K or 8K DCI sensor resolutions. The main thing I'm going to talk about is the rumored speed of these sensors. The 8K sensors have a scan speed of 5ms in DGO mode. DGO mode I do believe will reduce the overall speed of the sensor, but even without that, let's assume it's 1:1. That means that Canon is reading 4320 rows in 5ms, for a 1/200th electronic shutter speed.

Extrapolating the speed of the cinema sensors to a stills camera isn't a perfect science. Atypically a stills camera will run at a deeper bit depth than a video camera. This usually slows down the stills camera readout speed. For the sake of this comparison, we are going to assume that Canon because of the stacked sensor can output 14-bit data at the same speeds for a stills camera. This may be overly optimistic. A stills camera with a vertical resolution of around 4320 rows by 6480 columns is a 28mp full frame sensor, that should have a sub 5ms readout speed. A high resolution R5 style camera with a 100MP stacked sensor would be around 12247 x 8165, which would be a 9.5ms readout speed. As a basis of comparison, the R5 has a readout speed of 17ms - certainly no slouch in that department.

In other words, Canon has upped its game considerably with these sensors.

What is a stacked sensor?

Simply put, a stacked sensor is actually two or more substrates. Each substrate is fabricated independently and then sandwiched together to make a sensor. One substrate contains the pixels, and the other substrate contains the logic. In some sensors, there's even a third substrate, which commonly contains memory.

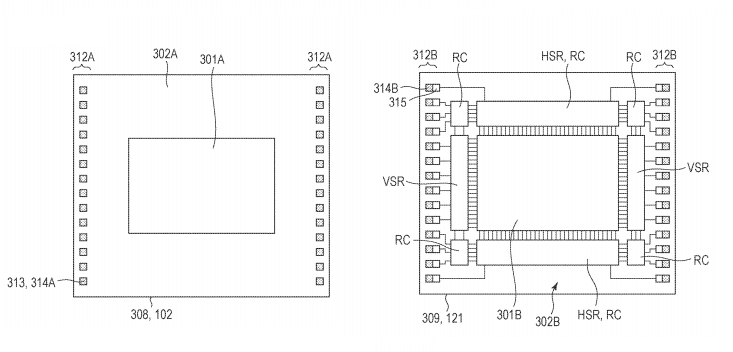

In this image from one of Canon's sensor patents, you can see that the top pixel later (left side) has pixels in the region of 301A. The bottom layer contains more complex containing ADC's, switching transistors, and whatever other logic Canon wants to add to the sensor.

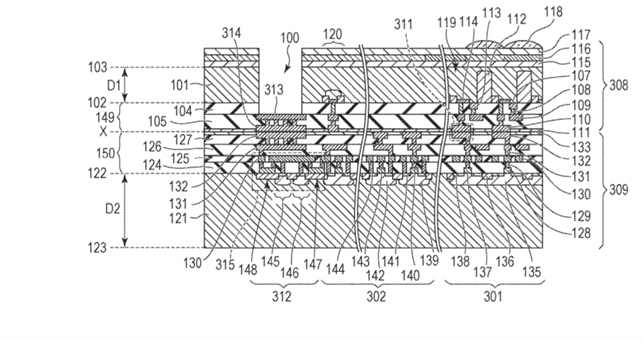

Below is a side image of a stacked sensor from one of Canon's more simplistic stacked sensor patent application designs. In this design, there are two substrates. 308 and 309 are the two substrates. 308 as you can see is a pretty simple substrate, there are photodiodes (112) and not much else.

What can Canon do with a stacked sensor and what are the benefits?

The difference between a stacked sensor and a normal sensor is that on a normal sensor you simply don't have the room to stuff all the electronics onto the one substrate efficiently. Whereas a stacked sensor, you can have different areas of the electronics substrate for ADC's, memory, switching circuits, etc all separate from the pixels themselves. It also provides some heat distribution and isolation not possible in a single substrate sensor. The faster the sensor runs, the more power it requires, and thus the more heat it generates during operation.

Stacked sensors allow for design and also fabrication flexibility. The pixel section doesn't need to be small design rules, as the pixels themselves are fairly course in their design. The pixel substrate can be fabricated on older (and cheaper) machines designed to create sensors. The electronics substrate is simply like any other integrated circuit chip that usually has smaller design rules. This substrate could even be production outsourced to another company's fabrication plant. Canon, for instance, does this with DIGIC. DIGIC chips are designed in-house but actually fabricated somewhere else.

One of the other benefits is the sensor design while more complicated can also contain more electronics and "brains" than before. A stacked sensor also opens the door to far more efficient global shutter designs as well, since with a global shutter you have to have memory for each pixel. That becomes much easier to design with a stacked sensor.

If you've been following our plethora of stacked sensor patents, Canon has dreamt up quite a few variations of a stacked sensor. Some of the more notable ones include very high speed stacked sensors. I liked this patent as it may actually see usage in Canon's cinema's cameras because it details ways of cooling a stacked sensor directly from the underside of the sensor. You can check out all the stacked sensor information that we've collected over the years here.

Canon has had to work considerably harder to compete with other company's sensors. They have fine-tuned their processes and sensors to the point where their FSI (front side illumination) based sensors almost rivaled the best BSI (backside illumination) sensors created to date. Now, Canon gets to use that technological know-how to jump into the stacked sensor space. All of a sudden Canon sensor engineers have a large amount of freedom that they never had before.

Interesting times.

Richard CanonNews

Richard has been using Canon cameras since the 1990s, with his first being the now legendary EOS-3. Since then, Richard has continued to use Canon cameras and now focuses mostly on infrared photography. Richard is the founder and editor of CanonNews since 2017, and has worked as a writer on CanonRumors and other websites in the past.

Other posts by Richard CanonNews